Banana chips are a popular snack enjoyed worldwide for their crispiness and unique flavor. As demand for these tasty treats continues to rise, understanding the manufacturing cost in a factory setting becomes crucial for producers and entrepreneurs. This article delves into the key factors influencing the cost of manufacturing banana chips, providing insights into the production process and associated expenses.

Raw materials:

Bananas: The primary raw material for banana chips is, of course, bananas. The cost of bananas can vary based on factors such as variety, seasonality, and location. Suppliers and manufacturers need to establish reliable sources to ensure a steady and cost-effective supply.

Oil: Most banana chips are deep-fried, requiring cooking oil. The type and quality of oil used can impact both the production process and the final product’s taste. The cost of oil is a significant consideration in the overall manufacturing expense.

Seasonings and flavorings: Depending on the desired flavor profile, additional ingredients like salt, sugar, and spices are used. The cost of these seasonings contributes to the overall manufacturing cost.

Production process:

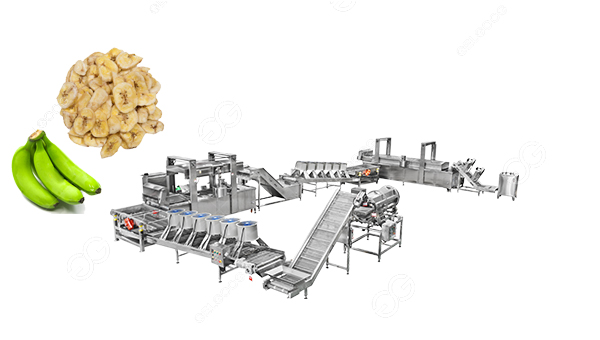

This process main include the banana chips production line cost.

Peeling and slicing: The first step involves peeling and slicing the bananas. This can be done manually or using specialized machinery. Manual labor costs, if applicable, and equipment depreciation contribute to the production cost.

Frying: Deep-frying the banana slices is a critical step in achieving the desired texture and taste. The cost of energy to heat the oil, as well as the efficiency of the frying process, affects the overall manufacturing cost.

Seasoning and packaging: After frying, the banana chips are seasoned and packaged. The cost of the seasoning ingredients and the packaging materials, including labels and bags, are significant factors in determining the total production cost.

Quality control: To maintain product consistency and quality, factories implement quality control measures. This may include personnel, equipment, and testing processes, all contributing to the manufacturing cost.

Labor costs:

Skilled and unskilled labor: The production of banana chips requires both skilled and unskilled labor. Skilled workers may operate machinery and oversee quality control, while unskilled labor may be involved in peeling. Labor costs include wages, benefits, and training expenses.

Overhead costs:

Utilities: Energy costs, including electricity and gas for cooking and packaging processes, contribute to overhead expenses.

Facility maintenance: Routine maintenance and repairs of equipment and the production facility add to the overall manufacturing cost.

Transportation: The cost of transporting raw materials to the factory and distributing finished products to retailers or consumers should be factored into the overall cost.

Understanding the manufacturing cost of banana chips in a factory involves analyzing various components, from raw materials to labor and overhead expenses. By carefully managing these factors and optimizing the production process, manufacturers can strike a balance between cost-effectiveness and delivering a high-quality product to meet the growing demand for banana chips in the market.

Price of all these machine