As a highly nutritious, easy-to-store, and versatile food ingredient, banana powder has seen a growing demand in the food processing industry in recent years. This project aims to build a banana powder manufacturing plant to meet market demand and promote the coordinated development of local agriculture and industry.

Project Goals

Establish an efficient banana powder production line to promote the development of local banana planting industry, provide employment opportunities, promote regional economic growth and meet the international market demand for high-quality banana powder.

Production process

The production process of banana powder includes the following main steps:

- Raw material collection and screening: Purchase high-quality green bananas and remove damaged or rotten fruits.

- Washing and peeling: Wash the bananas and peel them mechanically or manually.

- Slicing and dehydration: Cut the peeled bananas into thin slices and dehydrate them by hot air or freeze drying technology.

- Crushing and sieving: Crush the dried banana slices and filter them through a sieve to obtain a uniform and fine powder.

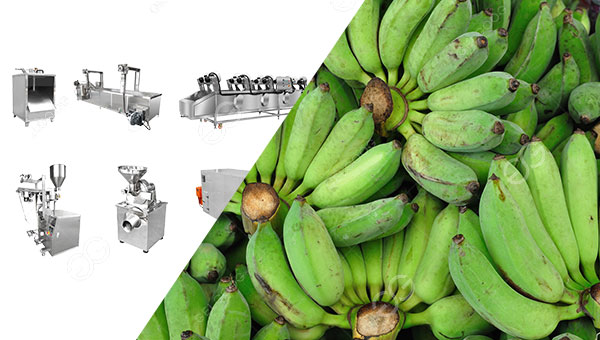

Main equipment:

Following are the key equipment required for a banana powder manufacturing plant:

- Banana cleaning machine: removes dirt and impurities from the surface of bananas.

- Slicer: slices bananas evenly to prepare for the subsequent dehydration process.

- Drying equipment: removes moisture from banana slices to ensure long-term storage of the finished product.

- Powder grinding machine: Process the dried banana slice into powder.

- Screening machine: Filter the larger particles in the powder to ensure product quality.

- Packing machine: Pack the banana powder into packaging bags according to the predetermined specifications.

Investment Budget

According to the equipment configuration and plant construction requirements, the preliminary budget is as follows:

- Equipment procurement: about 100,000 US dollars.

- Plant construction and decoration: about 100,000 US dollars.

- Staff training and operating funds: about 30,000 US dollars.

- Note: The cost is different when comparing different production scales.

Feasibility Analysis

- Market demand: Banana powder is widely used in baking, infant food, functional food and other fields, and has huge market potential.

- Technical feasibility: The production process adopted is mature, and the equipment has a high level of automation, which can meet the needs of large-scale production.

- Economic benefits: With low raw material costs and diversified sales channels, the expected investment return period is 2-3 years.