Brazil Customer Ordered Banana Chips Production Line

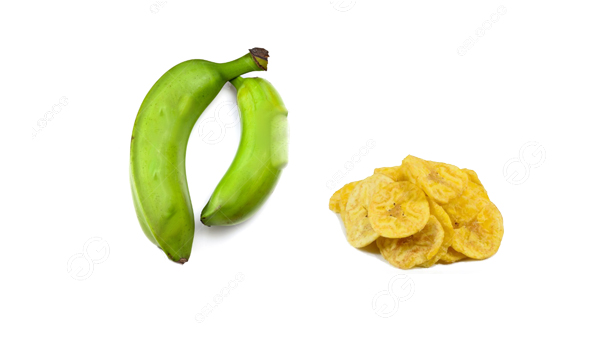

In a move signaling ambitious growth plans, a customer in brazil has recently made a strategic investment in our banana chips production line to establish a new factory. This decision marks a pivotal moment in the realm of snack production, reflecting a proactive approach to meeting the escalating demand for high-quality, wholesome snacks. Banana chips have garnered widespread popularity among consumers globally, celebrated for their irresistible crunch and natural sweetness. As health-conscious consumers increasingly gravitate towards snacks that offer both taste and nutritional value, banana chips have emerged as a preferred choice due to their inherent health benefits and minimal processing. The decision by our brazilian customer to invest in a banana chips production line underscores their foresight and commitment to staying ahead of evolving consumer preferences. By harnessing the…