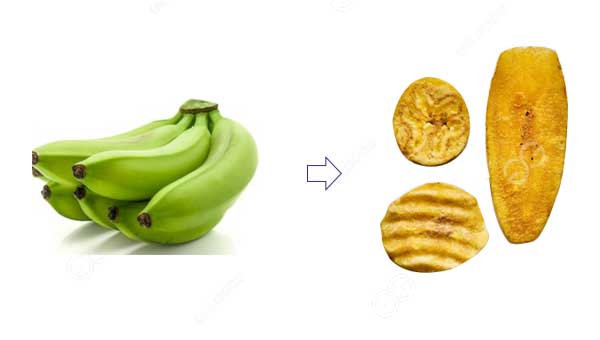

Plantain chips, with their crunchy texture and delectable flavors, have become a popular snack enjoyed by people around the world. But have you ever wondered about the journey these humble plantains undertake before reaching your palate? The process of producing plantain chips is a fascinating blend of agricultural expertise, technological innovation, and culinary mastery. In this article, we will take a closer look at what is the process of producing plantain chips.

Step 1: Sourcing and selection

The journey of producing plantain chips begins with the careful selection of high-quality plantains. These are grown in tropical regions where the climate is conducive to their cultivation. Skilled farmers monitor the plantations, ensuring that the plantains are harvested at the optimal stage of ripeness. This ensures the perfect balance of flavor, texture, and natural sugars.

Step 2: Harvesting and sorting

When the plantains are ready for harvest, they are carefully cut from the plants and transported to the processing facility. At the factory, the plantains are sorted based on size, ripeness, and quality. This step is crucial as it determines the uniformity of the final product.

Step 3: Washing and peeling

The plantains are thoroughly washed to remove dirt and debris. After washing, the peel is skillfully removed using specialized machinery. The peeled plantains are then inspected once again to ensure that no remnants of the peel remain.

Step 4: Slicing

Once the plantains are peeled, they are sliced into thin, uniform pieces. Advanced slicing machines ensure precision and consistency, resulting in even cooking and crunchiness in the final chips.

Step 5: Pre-treatment

To maintain the color and flavor of the plantain slices, they may undergo pre-treatment processes. This can involve blanching, where the slices are briefly immersed in hot water, or dipping them in a solution that prevents discoloration.

Step 6: Frying

Frying is a pivotal step in the process that imparts the characteristic crunch to plantain chips. The slices are carefully placed in hot vegetable oil, where they undergo a transformation from soft slices to crispy chips. The frying time and temperature are tightly controlled to ensure that the chips are evenly cooked without becoming overly greasy.

Step 7: Seasoning and flavoring

After frying, the chips are drained of excess oil and transferred to seasoning drums. This is where various flavors, such as salt, pepper, spices, or specialty seasonings, are added. The chips are tumbled in the seasoning mixture, ensuring an even distribution of flavors.

Step 8: Cooling and packaging

Following the seasoning process, the chips are cooled to room temperature to preserve their crispiness. They are then weighed and packaged into various sizes and formats, including bags, boxes, or containers. Modern packaging technology incorporates features to maintain freshness and extend shelf life.

Step 9: Quality control

Throughout the entire process, quality control measures are in place to ensure that the plantain chips meet strict standards for taste, texture, and safety. Samples are regularly tested to ensure consistent quality, and any imperfections are addressed promptly.

The entire production process is completed by a fully automatic banana chip production line, which requires less labor and meets the production needs of modern factories.